I had precut the outer keel over the winter. I also laminated the false stem using the inner stem as a mold. Both were made from mahogany. I had to wait to make the skeg until the inner kell was attached to accurately cut the skeg length.

Before attaching the outer keel I cut the 7/8″ wide outer keel slot starting with a sabre saw for a rough cut then used a router to make the finished cut. Attaching it to the hull was a simple matter with bronze screws and epoxy.

Outer keel attached with bronze screws and thickened epoxy.

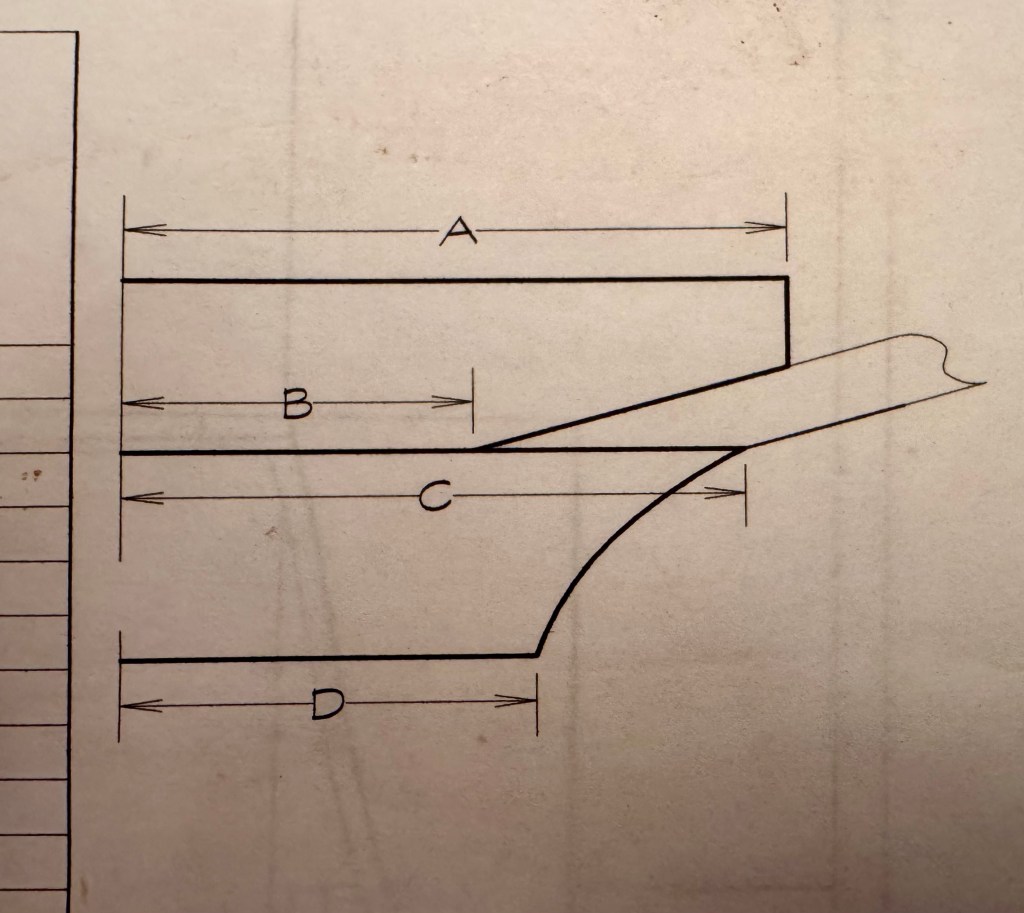

Before installing the keel I tapered the edges according to the drawings from vertical at the bow to about 45 degrees at the skeg end. This rolling bevel would eventually be cut concave with a scraper and sand paper. It was a particular Herreshoff detail.

Concave profile of outer keel.

Once installed I rough cut the inner keel with a sabre saw and used the outer keel slot as a guide for the final finish cut with a router.

Final keel slot and concave keel taper.

The skeg is 3/4″ solid mahogany. I made a template of the keel curvature to cut the keel attachment edge. It was screwed, through bolted (bronze) and epoxied to the outer keel.

The false stem was screwed (bronze) and epoxied to the inner stem and scarfed to the forward end of the outer keel. It fit nicely as it had been laminated over the inner keel. Then it was trimmed down to the final stem profile.

False stem.

Now it is time to paint.

Leave a comment