Herreshoff’s shear strake is unusual in that it is made of one contoured piece of mahogany, as opposed to the usual construction of a flat shear strake board with a separate rub rail. Clearly it is a lot of work to fashion so I assume Herreshoff’s shop had a custom blade for a shaper to make quick work of it. I do not have such a blade.

I first made a small mock up to determine what tools to use to get the profile.

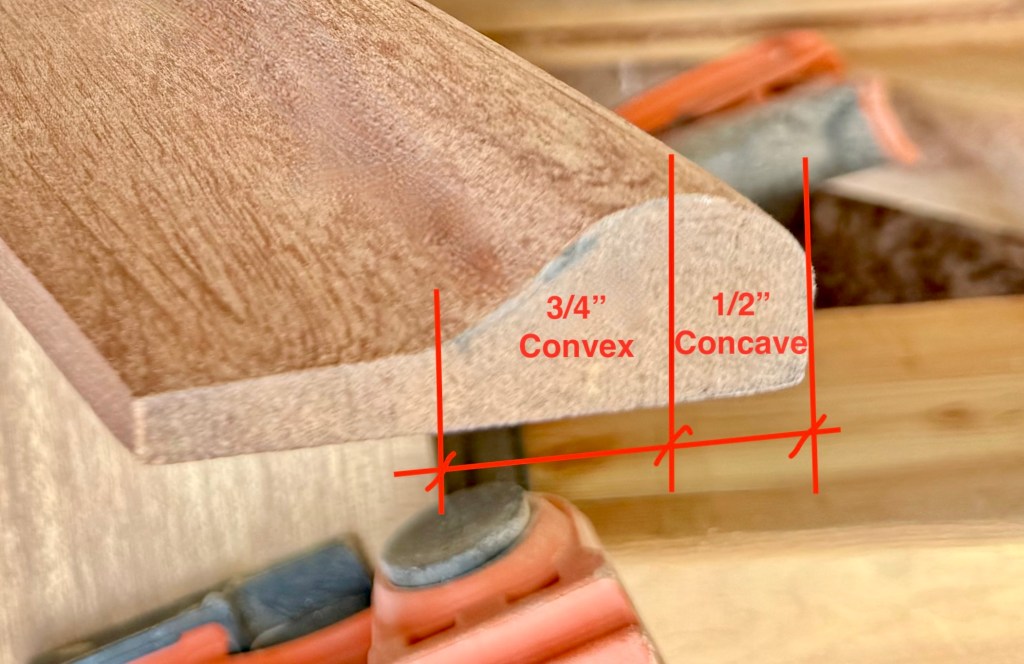

Mock up

Starting with a 1″ thick 18′ long piece of mahogany the object of the game was to cut away just the right amount of material to achieve the contour.

The pair of roughed out shear strakes.

The bulk of the material was cut away with a dado blade on the table saw. As the strake is curved this was difficult – the strake is curved in both directions. It was crudely cut, but that was just to reduce the amount of material so that I could use convex and concave router blades to get close to the rounded contoured face. I used two different router bits – one 1/2″ concave and one 3/4″ convex. Any left over material was removed with a hand plane. I made an exact negative profiled mold from some rigid insulation, attached 40 grit sand paper to the inside, and sanded the profile smooth.

Then it was a simple matter to hang it on the hull. As it would be bright finished I did not use screws to attach them, just clamps and epoxy. As there would be shear clamps, hanging knees and bulk heads screwed from behind into the back side of the shear strake I was not worried about the lack of screw strength. It bent easily onto the molds and hit the tick marks perfectly.

I trimmed off the ends flush and with a few passes with a hand plane to begin the tapers fore and aft to transition the curve to a flat and the two signature Herreshoff shear strakes are installed.

Leave a comment