Coquina has two masts, main and mizzen, two booms and two gaffs. Doug’s drawings dedicate an entire page to them. He has drawn full size profiles of all the jaws with copious notes and dimensions. Again, his accuracy is evident.

For this build I decided to use Sitka Spruce for the spars. In the past I had just used Douglas Fir. Basically from a 2×4 hand picked for straight grain and few, if any, knots. It was tedious to say the least. Rarely did I find any without at least one knot. The use of Sitka would assure that I could get straight grain and no knots. Also it would be well suited to the Coquina – light, bendy, but strong. The only problem was finding it locally.

After looking about for a while it dawned on me that I might try M.L. Condon Company. I have used them in the past for my business specifying miles of different veneers for large building projects. While I only needed a small amount of lumber I was worried they would not be interested. After a quick call, they were indeed interested and exceedingly helpful and responsive. Apparently wooden boat building was a side line of the fellow I talked to.

So I ordered two 20′ long 2″ thick rough cut planks of Sitka for the spars as well as two 18′ long, 10″ wide and 1″ thick rough cut mahogany planks for the signature Herreshoff shear planks. I added some other clear grained mahogany and fir planks for future use. Originally fearing a large cost for the lumber and shipping I was pleasantly surprised at how reasonable it was. Within three days a small pickup truck showed up with a pleasant man, his wife, and my order – it was the only thing he was delivering that day. I definitely recommend Condon for lumber if you are somewhat local to White Plains, New York.

The first step was planing down the Sitka to surface it. Then I focused on the birds mouth main mast. After calculating the dimensions needed for the eight sides I ripped the lumber into 3/4″ thk. strips. Then tapered them according to Doug’s offsets on the table saw, hand planed them to the designed profile and cut a 45 degree “V” on one side (to seat with the 90 degree corner of the adjacent strip, making up an octagon). In order to get a clean and accurate V cut I rigged up a few feather boards to guide the wood accurately.

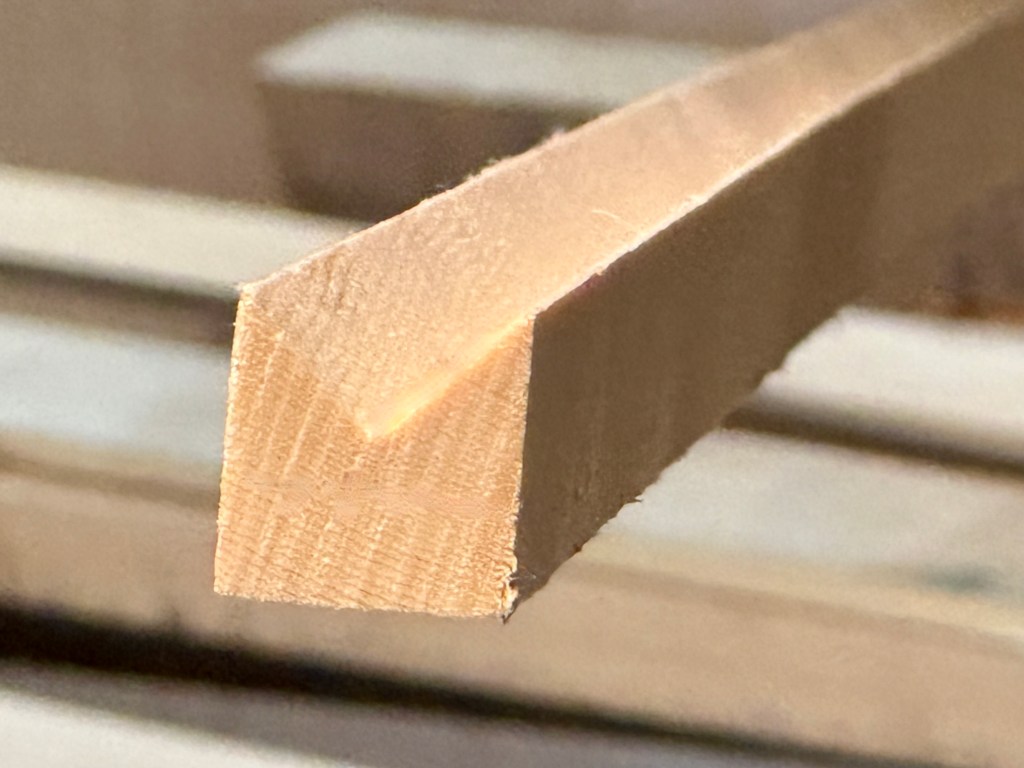

V shaped stave for 8 side birds mouth main mast.

After dry assembly to test the fit (which turned out to be very good) I then wet the edges down with epoxy and added epoxy with filler. Assembling them is always a slurry mess, but got them together with the help of some tape. Then hose clamps went on, tightened, and the squeezed out epoxy was removed to help with cleanup. I slightly adjusted the length of the mast staves to assure it was straight.

I then moved on to the mizzen mast. It was to be solid. I glued two sections together to make up the overall width. I find that a lamination helps to minimize warpage as opposed to a one piece mast.

The booms and gaffs were remarkably thin so I made them from a single length of Sitka. There was a bit of warpage on the smaller gaffs, but Sitka is so bendy it should be fine. They were all tapered according to Doug’s drawings. I hope the Sitka Spruce lives up to it’s strength reputation because they are VERY thin at their ends.

The gaff and boom jaws are made of white oak. The gaff jaws were steam bent to achieve their curvature. I made a mold of the shape with compensation for spring back from a thick piece of fir. Seems to have worked out well as the curvature aligns with Doug’s full scale drawings. The mold would only accommodate one half jaw at a time. Next time I will build one to handle at least two at a time. While the steaming did not take long I had to wait 24 hours for it to cool and dry. Eight days for four jaws was not an efficient use of time.

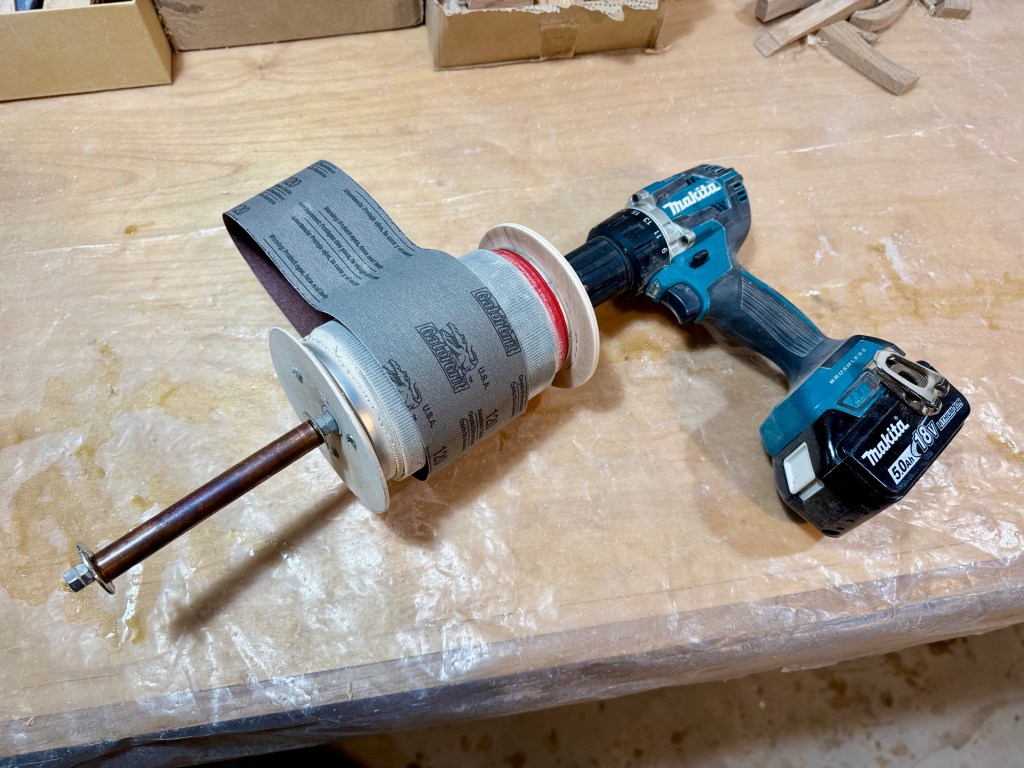

I used a hand plane to get each spar down to eight, then 16, then 32 sides. After that I used this home made concoction to sand them round and smooth. Great time saver.

Small white oak fittings were made for the rigging attachments on the spars. They were screwed and glued to the mast as located on the plans.

Eight coats of varnish later they were done.

Varnished jaws with leather bearing ends.

Leave a comment