With the weather getting colder (in the teens now) I had to move to my basement shop to work. I will return to the hull when it gets warmer.

The centerboard and rudder were scaled from the drawings. Making the centerboard first would allow me to build the centerboard case around it to make sure of a tight fit. The arch of the trailing edge used the pivot hole location as the anchor point. It was well marked and will be drilled when the case is built to assure proper alignment. The rudder is less precise and has some “shapely flair” which is really just eye-balling a nice shape.

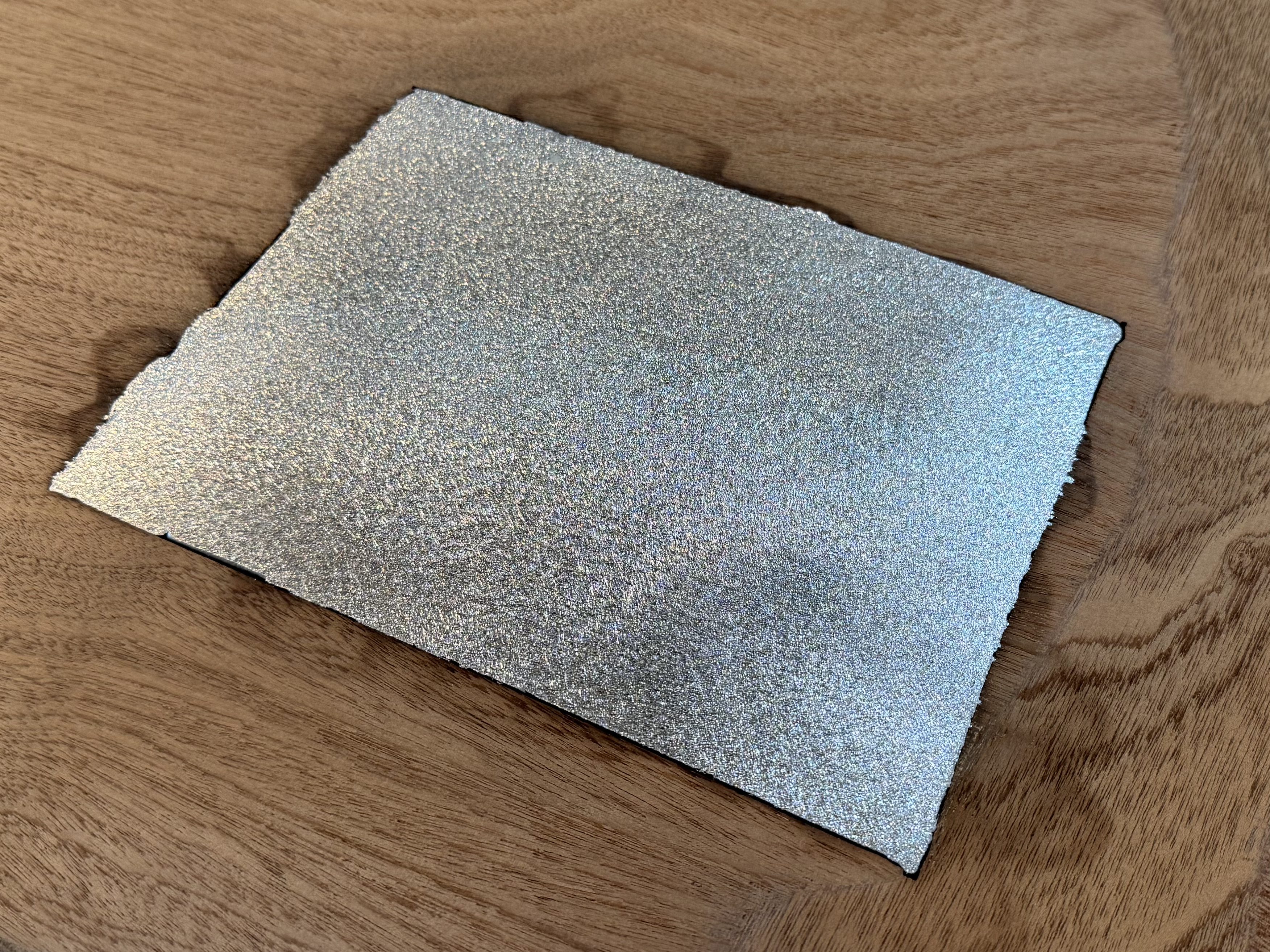

They are both made from 3/4″ marine mahogany ply and fiberglassed for strength. Trailing edges were tapered to a foil shape. The holes accommodate poured lead inserts to weight them down so they don’t float up. Bronze screws were put in the inner sides of holes protruding a bit to hold the lead tight. The surface of the lead was planed flush. The lead shrinks and pulls away from the inner edges as it cools, so liquid epoxy was poured into the gaps.

After finished sanding they were both fiberglassed for strength and wear resistance.

Leave a comment