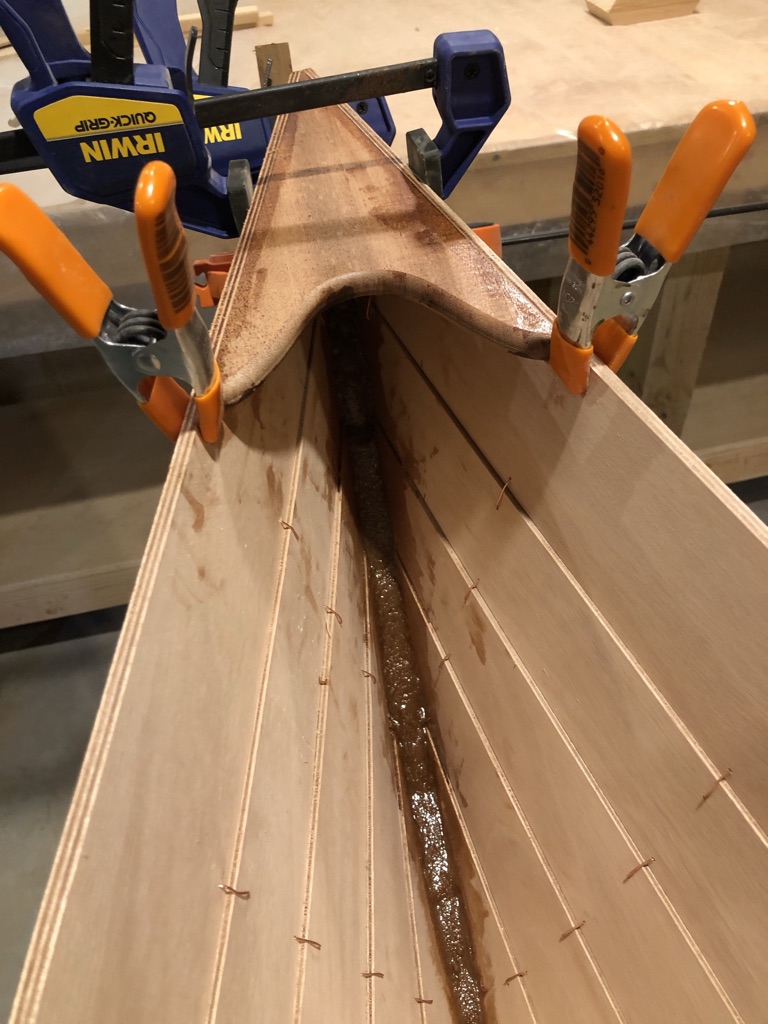

With the hull tightly wired together it was time to tack-glue it. The idea is to use filled epoxy in the seams between the wired holes to tack the planks together and attach the transom. I mixed up two-part MAS epoxy with a considerable amount of wood flour, put it into a plastic baggie with a corner cut off, and forced the mix into the spaces between the wired holes. This step is meant to hold everything together so the wires can be removed. It is not suppose to be a finished fillet edge. The blobs of filled epoxy were not easily controlled. I started with the transom.

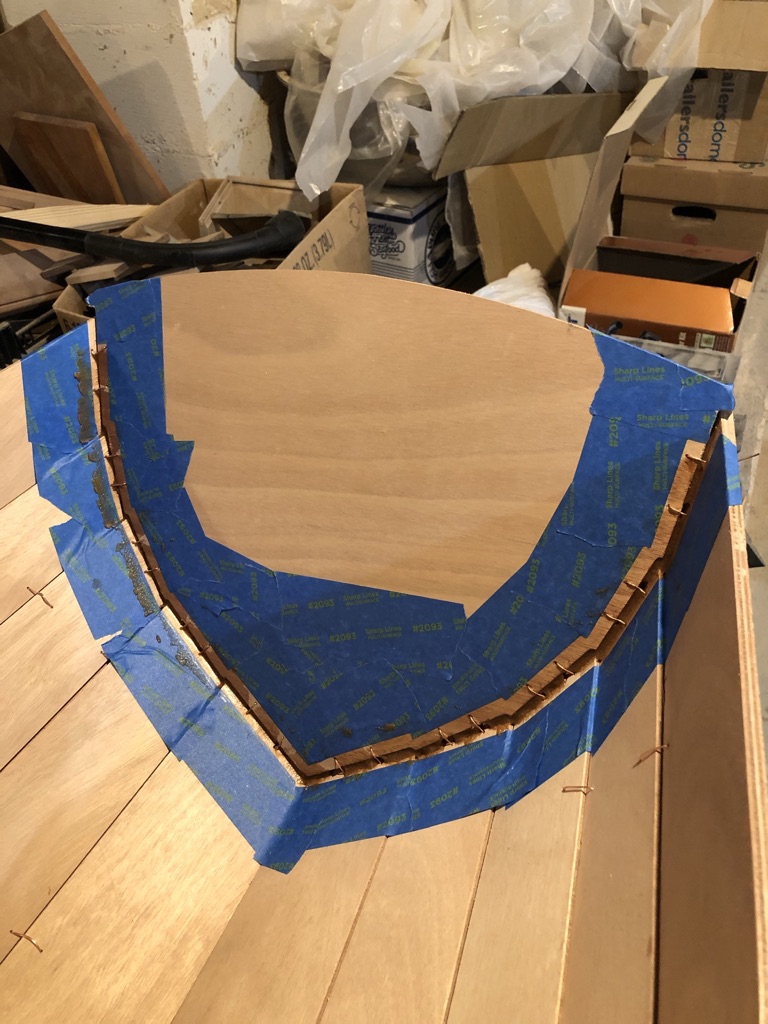

Then I moved onto the bow joint and breast hook. The bow joint required a considerable amount of goop and I did it in two layers. The first layer crudely filled the deep V joint, the second created a smoother appearance. The addition of a permanently fixed breast hook stiffened the bow area considerably.

First Layer of Bow Goop and Breast Hook Install

I did a test mockup to see how well I could smooth out the epoxy for the plank edges and the fillets. I found that a finger, well wetted with alcohol, smoothed things out nicely.

Then it was time to remove the few hundred wires! Some were glued in and others were bent and snagged, but I eventually got them out. Well, not every one as some pieces broke off in the holes! No worries. The soft copper would eventually be sanded flush.

Leave a comment