The kit arrived. The 18′ Wherry requires an amazingly small amount of wood. All parts are marine plywood except the breast hook and quarter knees which are 3/4″ mahogany. Also included were everything needed to build it: two-part MAS epoxy, copper wire, wood flour, silica, construction manual, and more. Apparently Chesapeake Light Craft has shipped hundreds of Annapolis Wherry kits.

First off, I sorted through the parts to understand what goes where. They were all well-labeled and keyed to the instruction manual.

Each plank was in three pieces, which meant scarfing. Scarfing was made easy by the “puzzle” joints cut into the joining ends. No need to do that careful diagonal planing to create your own scarf joints. Yahoo! All the parts were CNC-cut so the zigzagging finger joints were not as complex as they looked.

Gluing up the joints took very little time. The process was the same as ordinary scarfing – wax paper, pressure block, glue, and careful alignment. They went together flawlessly. Those puzzle joints are a remarkably clever idea. Strong design also.

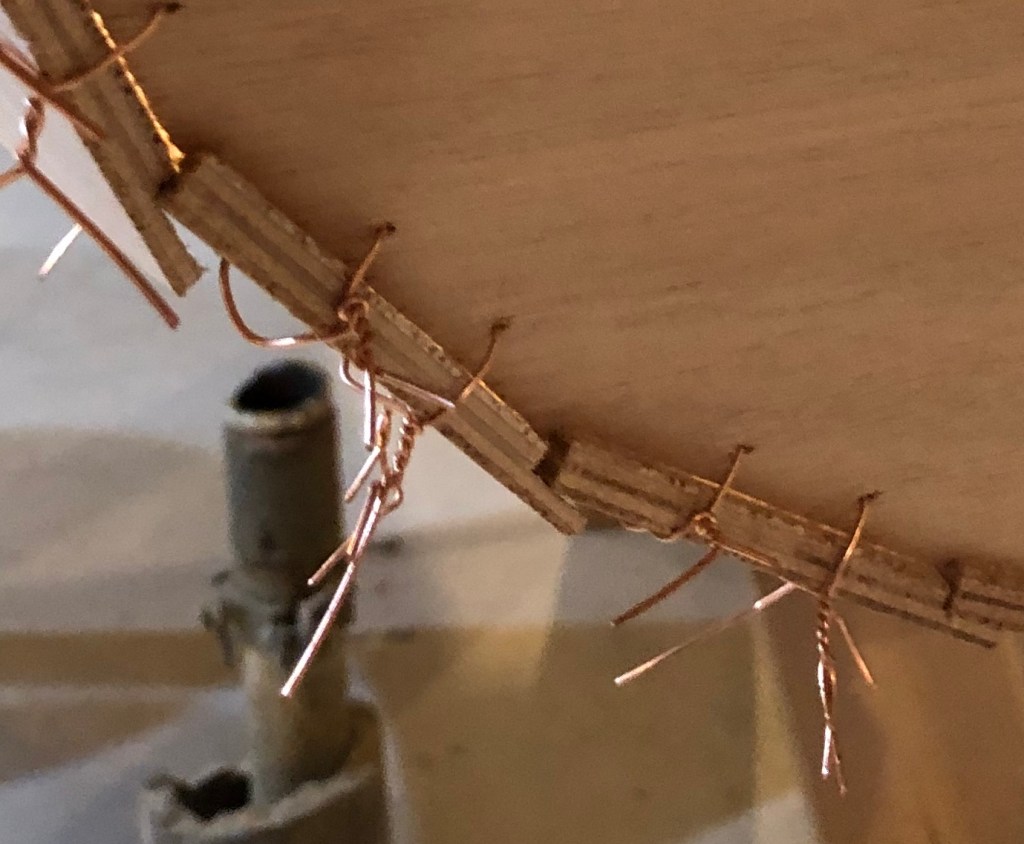

The planks had another clever CNC-cut feature. The long joining edges had what Chesapeake Light Craft calls a “Lapstitch” joint. This is essentially a rabbeted edge on one plank edge for the overlap of plank to plank. There would be no “tack and tape” seams here.

Cutting the gains of the planks at the bow is always rewarding. Knowing that the feathering you are doing as you cut will bring the planks together for a perfectly flat bow cutwater is always satisfying. The plywood cut easily with a well-sharpened shoulder plane.

Leave a comment