As the cost of this project was mounting I decided to make the sail myself instead of going to a sailmaker. To be clear, when I say “I decided to make the sail,” that meant Susan would be doing most of the work! She is an expert with her German sewing machine. Her machine is a home sewing machine, not an industrial one, so it took some improvisation. I found a great company, Sailrite, whose designer could design the sail, cut the panels, and provide the materials. The costs were a fraction of what a sailmaker would charge.

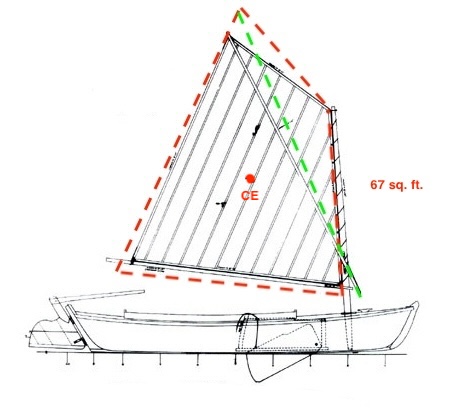

A Seaford Skiff was not a common boat, so the sail would have to be custom. After some back and forth with Sailrite, we decided on a sail draft layout. I slightly modified the “winter” sail profile given on the plans as it seemed small, and I would be adding reef points. I lowered the foot, extended the clew, and raised the head a bit. I calculated the CE for the new layout, and in the end added two square feet to the originally designed 65 sq. ft. The sail came with everything needed – CNC cut 4 oz. fabric panels, reinforcing patches, thread, basting tape, and seam backers – all except the cordage. They even had “how to” videos available for first time sailmakers.

Susan, always the perfectionist, did a wonderful job. I only had to take care of the grommets, reefing points, and rope work (and look over her shoulder). In the end it cost about $250 for everything (less than the cost of the rudder fittings!). We then took the sail out for a spin on the spars. We temporarily rigged it to see how we did.

The sail fit the spars perfectly and looked like it had been made by a professional sailmaker! Susan has a new career!

Although, as I studied it for a while, I began to wonder. How about a tops’l? Ha!

A Tops’l?… That’s for another day!

Photos of Seaford Skiffs are extremely rare. I was able to find a couple of others as well as Mystic Seaport’s Helen Packer.

This one shows a robust rig, mast hoops, high peak, and a large (summer?) sail.

Here is one with a battened roach, high peak, and low foot.

Toward the end of construction we hauled the boat out to the yard to get a better idea of how sail and spars would look on the actual boat. We were very pleased. “Making it ourselves” was an enjoyable learning experience and we were quite proud. That said, I have a more nuanced appreciation for sailmakers. It is definitely an art.

Leave a comment