As far as the overall construction methodology I had decided to reduce the scantlings with this build. The 1870s originals used a lot of White oak for the stem, stern post, keel, transom, rudder, and ribs. The hull would have been carvel-planked in 1/2″ cedar. While this would have guaranteed a sturdy build, ideal for the kinds of uses the boat was originally intended, it would have been very heavy. I would not be sailing her in winter gales if I could help it. Moreover, in the 1870s epoxy did not exist.

Instead, I decided on laminated Doug fir for the stem and stern post, 1/4″ cedar to strip build the hull, mahogany for the keel, marine mahogany plywood for the decks, centerboard trunk, and rudder. As the hull, at 1/4″ would be thin, I planned to glass her inside and out with two layers of 6 oz glass. I coated everything with several coats of epoxy, especially any end grain ply. This ensured she would not leak, be strong enough for the uses in my area, and there would be no need to do traditional caulking of the hull. I learned from my “big” boat, which is edge glued, that it made the hull very stiff. This limited any torquing while under the stresses of wave and wind forces. That stiffness transfers the wind loads more directly from the sails to the hull and keel. Additionally, without that movement the boat is quite fast.

On another note, in addition to having the structural qualities of laminated wood, Doug fir was easy to find, quite cheap, and came in a variety of lengths and thicknesses. In fact, by rummaging around the piles of Doug fir at my local yard I was able to select straight-grained knot-free 2x4s and 2x6s. Amazing they exist today but they are there if you look hard enough – and they don’t cost any more than the warped, cracked, knot-filled ones!

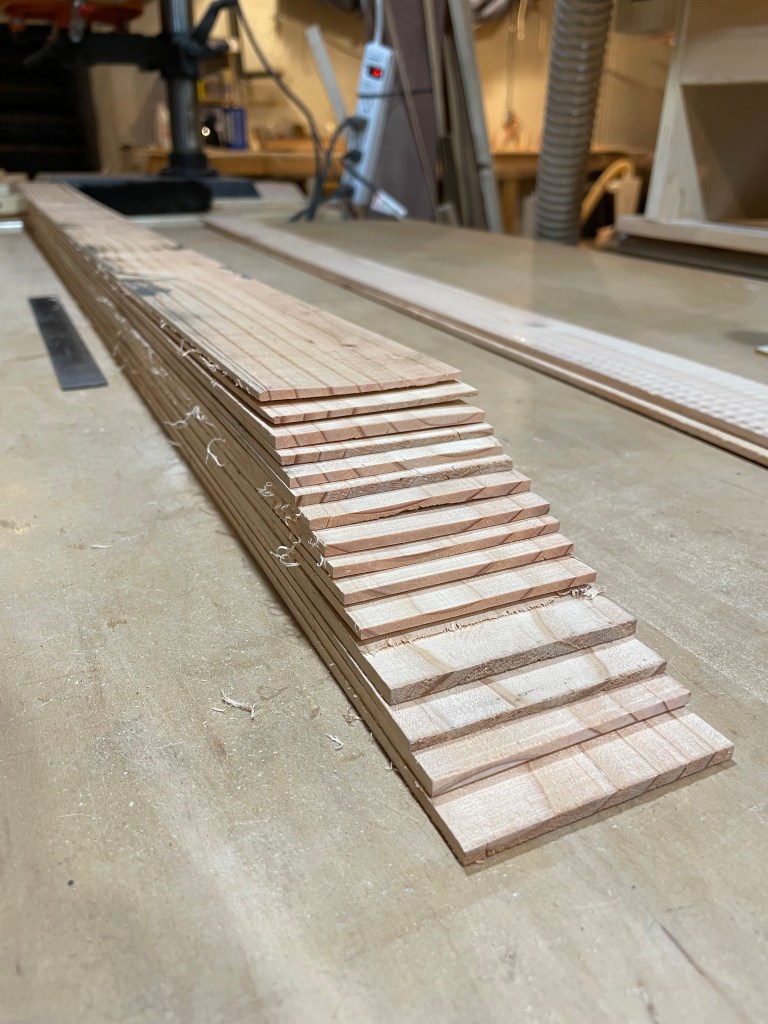

In preparation for the laminations, I cut the fir into appropriate strip thicknesses depending on the bend required. Some were as thin as 1/8″, others were up to 3/8″.

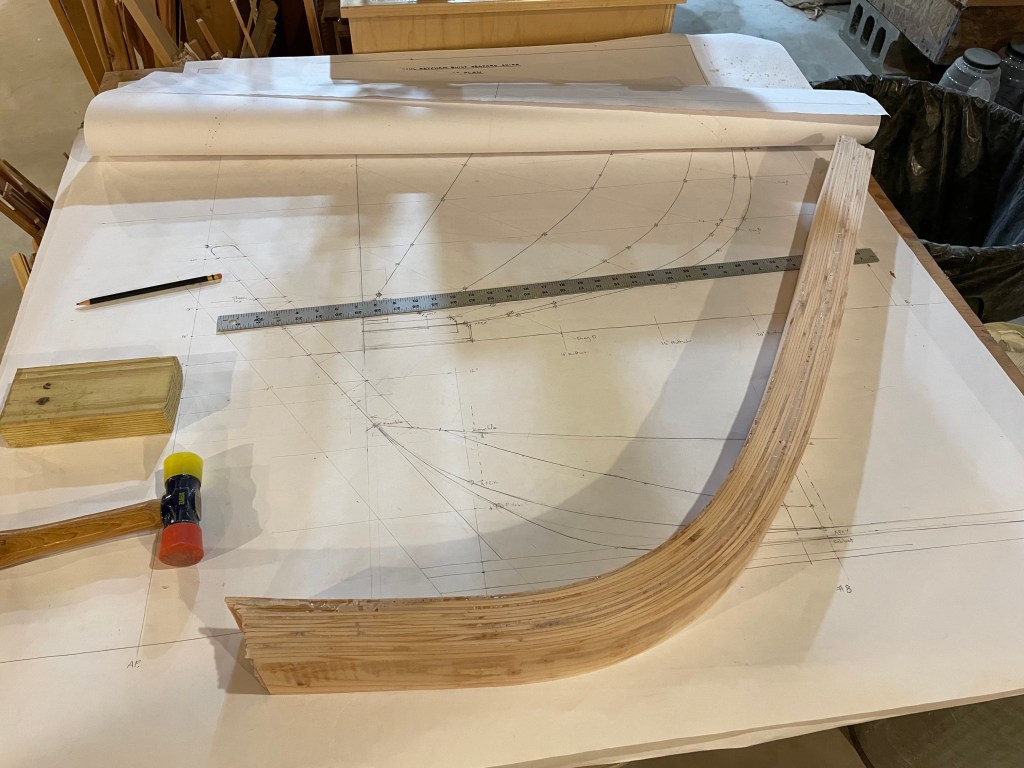

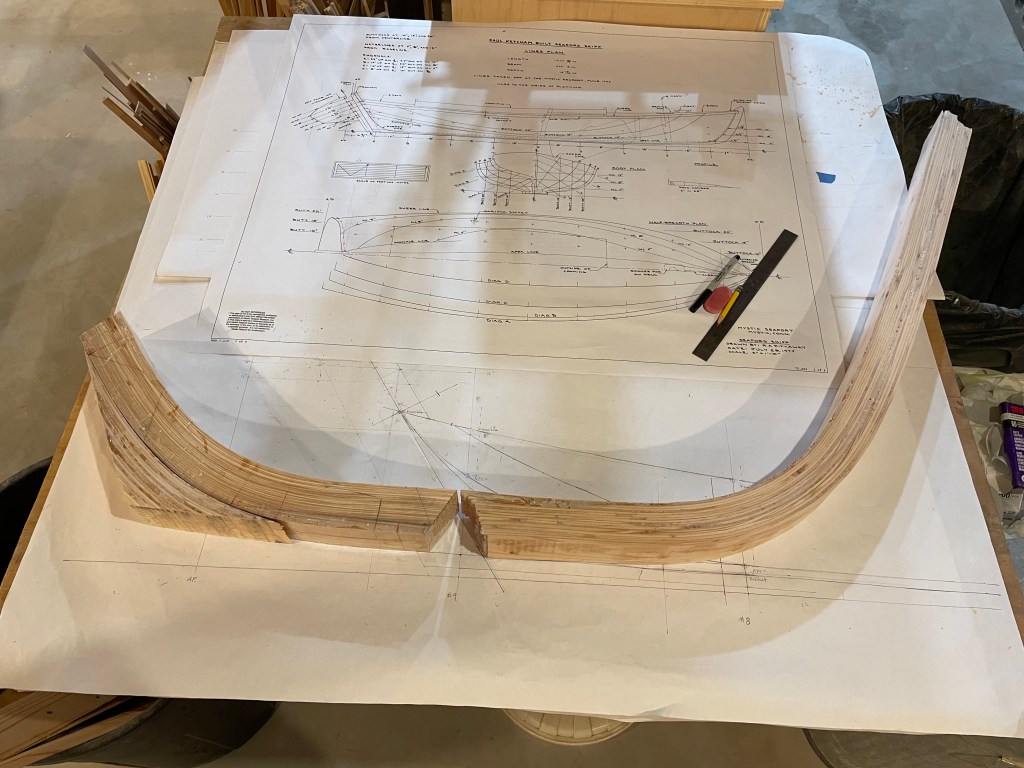

The glue ups went smoothly. There was just one breakage as I tried to use a slightly too thick lamination in a tight bend. The usual “pushing the envelope” kinda thing. The worst part of glue ups is the waiting – 24 hours for the epoxy to dry. I think most of my time building this boat was waiting for goop and paint to dry!

Using a lamination as a mold

Stem Lamination

Stem and Stern

Leave a comment